Metal Manufacture

Custom

manufacture of

metal structures: quality, experience and competitiveness from the company

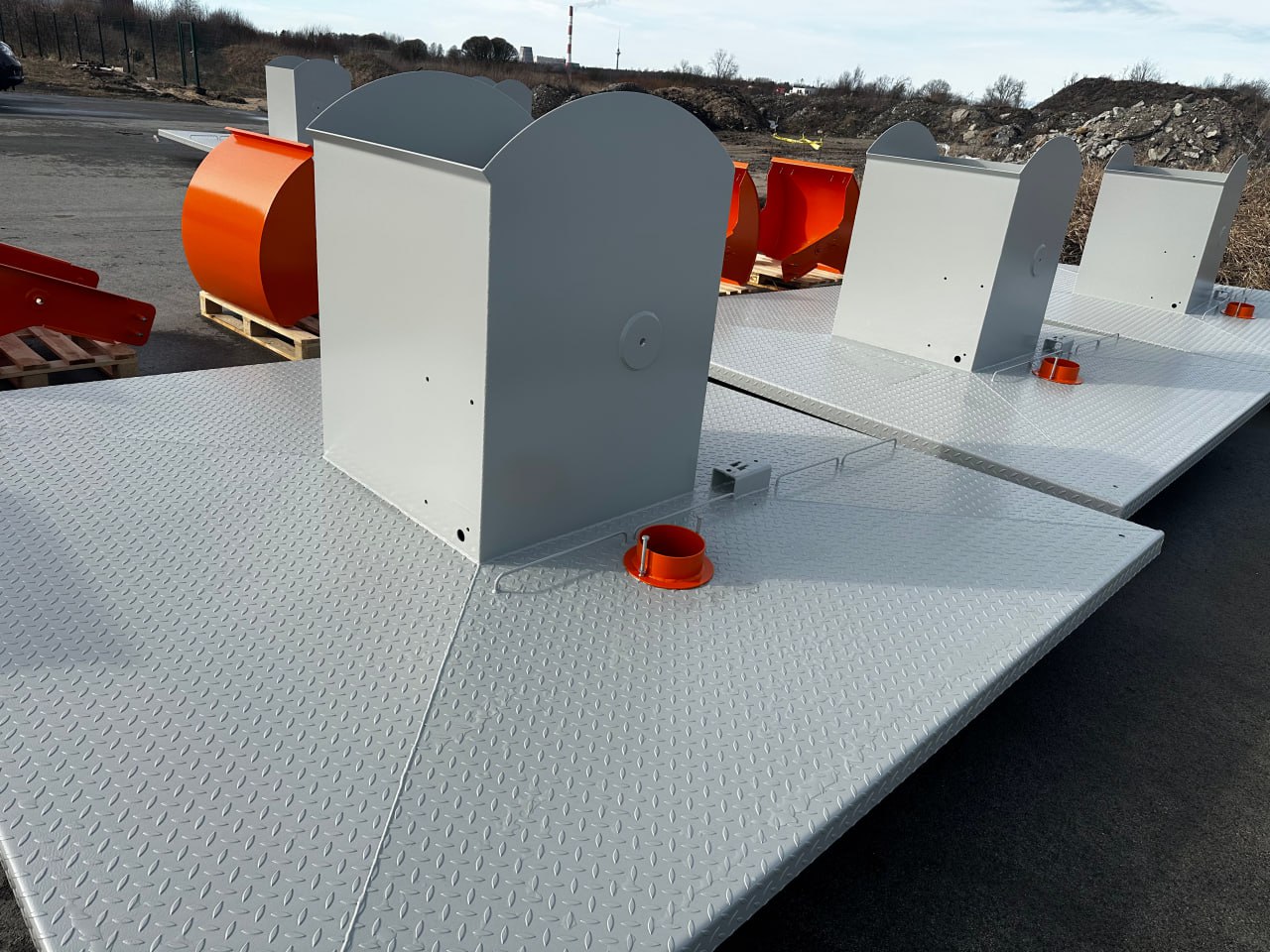

We offer our customers the services for the manufacture of small, medium and large-sized metal structures. We carry out both prefabrication (i.e. assembly and welding works), and complete product manufacturing.

During the period of the company’s existence, we have acquired valuable knowledge and experience, which has allowed us to keep a high level of quality and competitiveness in accordance with international requirements.

Having qualified personnel with more than ten-year experience in the field of metal structures manufacturing, we are ready to help our customers to solve any problem.

We accept orders for manufacturing of

Metal Structures

- Hangars

- Farms

- Platforms

- Stairs

- Railings

- Fences

- Gates

- Pillars, beams and other

Mechanical Engineering

- Foundations

- Conveyors

- Silo constructions

- Tanks

- Metalworking elements

- Woodworking elements

- Other

Other constructions

- Industrial equipment

- Design solutions

- Furniture elements

- Interior elements

- Other

Fabrication of structures and welding works are carried out in accordance with EN 1090–2, EN ISO 3834–2.

The production area of the enterprise is divided into:

- Material and component placement

- Placement of finished products

- Locksmithing (material sawing, drilling, processing of holes, edges)

- Plasma cutting

- Bending machine operations

- Work with coordinate-punching press (Punch)

- Work with thin metal (guillotine, rollers for sheet metal rolling)

- Works on assembly and tooling of structures

- Welding works

- Works on cleaning and grinding of structures

- Assembly of attachments

- Final assembly operations

- Product packaging

- Visual inspection of welds, line and plane deviations

- Inspection of bolted joints

- Control of paint-and-lacquer coating

- Final inspection before dispatch of products

Manufacturing products in

accordance with international standards

Manufacturing processes

Getting acquainted with the order information

- Technical documentation, level and requirements

- Terms and conditions of production

- Price quotation, drawing up a contract

Manufacturing of products

- Purchase of material and components

- Input control of material and components for manufacturing

- Prefabrication work

- Assembly, welding (EN ISO 5817 C, EN ISO 13920 BF, by default)

Inspection of welds, line and plane deviations (VT2 ISO 9712) - Product surface treatment (painting, zinc plating, galvanising, and other)

- Inspection of the surface treatment of a product

- Final assembly of components and equipment

Dispatch of finished products

- Control of finished products

- Drawing up and sending documents to a customer

- Packaging of products, dispatching

Manufacturing of products

- Purchase of material and components

- Input control of material and components for manufacturing

- Prefabrication work

- Assembly, welding (EN ISO 5817 C, EN ISO 13920 BF, by default)

Inspection of welds, line and plane deviations (VT2 ISO 9712) - Product surface treatment (painting, zinc plating, galvanising, and other)

- Inspection of the surface treatment of a product

- Final assembly of components and equipment

REHUNT 2025 © A reliable partner for your enterprise since 2016. Manufacture of metal structures. Staff recruitment.